An Unbiased View of Sheroz Earthworks

An Unbiased View of Sheroz Earthworks

Blog Article

The 30-Second Trick For Sheroz Earthworks

Table of ContentsIndicators on Sheroz Earthworks You Should KnowSheroz Earthworks for BeginnersRumored Buzz on Sheroz EarthworksSome Ideas on Sheroz Earthworks You Need To KnowSheroz Earthworks Fundamentals ExplainedNot known Details About Sheroz Earthworks

Today, Smart Construction Remote links over 700 devices on jobsites to offices, saving thousands of hours formerly invested by jobsite managers, surveyors and engineers commuting from offices to jobsites. So to sum up, the initial 10 years of Komatsu's smart maker control have been noted by a years of special advancement, regular discovering and growth with consumers.

Below's to the next ten years! Content created in association with Komatsu.

In the quickly evolving globe of building and construction, precision and efficiency are vital. 3D device control, a system that makes use of general practitioner and other sensors to lead machinery with determine accuracy, is changing the industry - https://dzone.com/users/5206373/sherozau.html. From its early days of 2D guidance, this innovation has advanced drastically, making tasks that once needed hands-on intervention currently feasible with minimal human input

In building, it makes certain that every cut, fill, and grade is executed with surgical precision. Let's discover how this game-changing innovation functions. At the core of any kind of 3D maker control system are GNSS receivers and antennas, recording satellite signals to determine the equipment's exact place. Onboard computer systems and control boxes procedure this information and communicate with the equipment.

The Facts About Sheroz Earthworks Revealed

This includes establishing up GNSS receivers, calibrating sensing units, and setting up the maker control software program - trimble gps. The magic of 3D machine control lies in its real-time data collection and handling.

Customer user interfaces supply real-time updates on the equipment's placement and required adjustments, making sure precise control. In building and construction, 3D maker control is made use of for earthmoving, grading, paving, and excavation, making sure jobs are finished to precise specifications.

How Sheroz Earthworks can Save You Time, Stress, and Money.

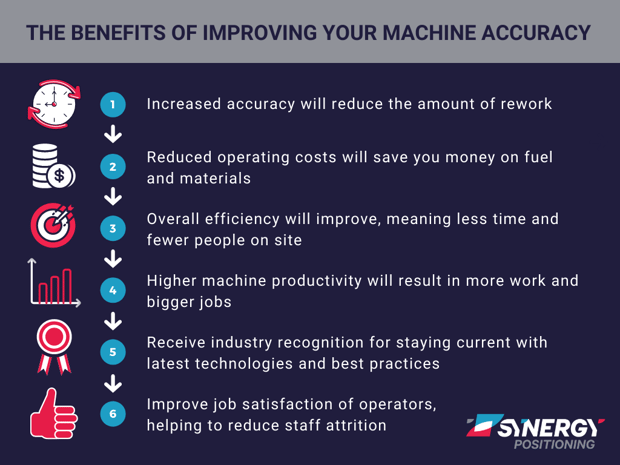

3D machine control significantly enhances efficiency by minimizing rework and reducing material waste, resulting in faster and more affordable task conclusion. The innovation makes sure every job is executed exactly as planned, resulting in constantly high-grade job. Among one of the most engaging advantages of 3D device control is the substantial price savings it offers.

Gas intake is optimised since machines operate better and prevent unneeded motions. Upkeep expenses are additionally decreased, as the equipment experiences much less deterioration as a result of precise procedure. In general, these financial savings contribute to an extra lucrative lower line for any job. By minimizing human error and restricting direct exposure to hazardous environments, 3D device control enhances employee safety and minimizes accidents.

From construction to mining, this technology guarantees jobs are carried out precisely and securely, minimizing expenses and enhancing end results. As developments proceed, the potential for 3D machine control to even more improve efficiency and safety grows. Accepting this innovation is essential for industry professionals wanting to stay affordable and attain the greatest criteria in their jobs.

Some Known Questions About Sheroz Earthworks.

Discover the future of accuracy and performance now! Likewise, look into our most recent YouTube video on the FJD H36 Motor Grader Control System to see the modern technology in action: View now.

For many years, we have actually seen drivers with great deals of experience do some outstanding things with their machines. Maybe they have an eye for adjustments that improve precision, or maybe they understand which attributes of their device to utilize and when to enhance efficiency or performance - https://profiles.delphiforums.com/n/pfx/profile.aspx?webtag=dfpprofile000&userId=1891233929. like it However with today's improvements in hefty devices modern technology, even skilled drivers can take advantage of a real-time aid to enhance their daily efficiency (topcon laser levels).

This is where machine control systems consider. A system with an in-cab tablet that integrates sensing units and GPS innovation can sustain accuracy and efficiency. Volvo Building and construction EquipmentLet's check out excavators as our initial instance. Some excavators feature device control systems that assist the operator via functions to automate the excavating procedure.

Sheroz Earthworks - An Overview

With this included precision, rework is practically gotten rid of, enabling the driver to finish the project on schedule and relocate to the next task. For those dealing with dangerous or challenging jobsites, remote-controlled options open brand-new opportunities. This outstanding add-on allows you to operate an excavator from a distance in locations with hazardous substances (like in a potash mine) or poor ground problems (like mud).

Maker control systems offer beneficial advantages to more than simply excavator drivers. If you have actually a vehicle come in with a target of 23 lots, your operator can fill their pail and dynamically weigh itoften without even being fixed.

This means the operator can see the specific weight of the tons they're about to dispose (topcon laser level). On-board considering provides real-time understanding right into the pail's load to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building EquipmentIf they dump 12 tons on the very first pass, the next container requires to consider 11 loads

Sheroz Earthworks Things To Know Before You Get This

The majority of procedures make use of an on-board evaluating application to guarantee that the load is exact prior to they send their trucks to the ranges, which is essential since the scale weight is what's utilized for payment and invoicing objectives. Several manufacturers consist of some type of weighing program on their loaders. Some likewise have attributes that allow firms to monitor and regulate the overall tons of multiple vehicles.

Report this page